Enhancing Efficiency: 3D Laser Scanning in Connecticut

Benefits of 3D laser scanning in Connecticut .Intro

In the heart of New England, Connecticut has actually always been a center of technology and technical innovation. As an engineer working in the state, I have witnessed firsthand the transformative power of emerging technologies. Among these, 3D laser scanning has actually become a game-changer in various sectors, from building and producing to historical preservation and beyond. Allow me to take you via my trip of discovering and using 3D laser scanning in Connecticut, highlighting how it has improved efficiency across different industries.

My First Encounter with 3D Laser Scanning

My preliminary encounter with 3D laser scanning was both enchanting and informing. It was during a project at a historic site in Hartford where the demand for specific measurements was important. The standard approaches were showing to be time-consuming and prone to human mistake. That’s when I was presented to a 3D laser scanning specialist from a regional company.

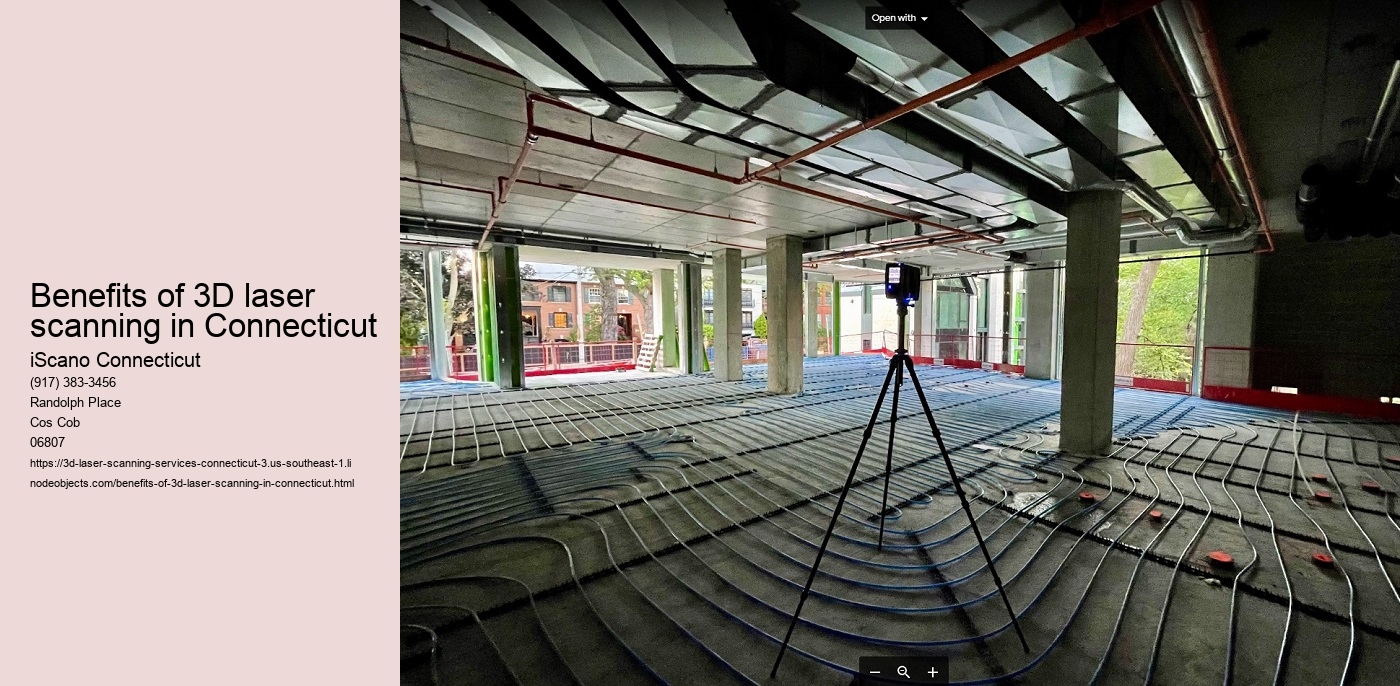

Viewing the scanner in action was like seeing a scene from a sci-fi movie. The gadget, placed on a tripod, discharged laser beam of lights that brushed up throughout the space, catching every min detail. Within minutes, we had a detailed 3D model of the entire room. This digital replica permitted us to examine and plan the restoration process with exceptional precision. The effectiveness and accuracy were past anything I had experienced previously.

Embracing the Technology in Building

Motivated by this preliminary experience, I started checking out the broader applications of 3D laser scanning in my field. In Connecticut, where construction projects range from modern-day skyscrapers in Stamford to enchanting colonial reconstructions in Mystic, the potential for this technology was tremendous.

One of the first major tasks where we executed 3D laser scanning was an industrial growth in New Haven. The website had numerous challenges, consisting of minimal access and tight deadlines. Standard checking methods would have needed multiple website visits and extensive hand-operated measurements, which might have postponed the job dramatically.

With 3D laser scanning, we were able to carry out a full website study in a solitary day. The scanner caught every facet of the terrain, consisting of topography, existing frameworks, and underground energies. The resulting 3D model supplied our group with a comprehensive and precise foundation for planning and layout. We might virtually check out the website, determine possible problems, and make educated choices without the need for constant physical inspections.

This effectiveness not just saved us time however also decreased expenses. By identifying and dealing with potential troubles early in the layout phase, we prevented pricey rework and hold-ups throughout building and construction. The specific measurements likewise made sure that materials were purchased accurately, decreasing waste and advertising sustainability.

Changing Production Processes

As I dove deeper into the capabilities of 3D laser scanning, I recognized its possible to reinvent manufacturing processes. Connecticut has a rich history of manufacturing, from aerospace parts to clinical tools. Accuracy is critical in these markets, and even the tiniest inconsistency can bring about significant problems.

I had the opportunity to work together with a leading aerospace producer in the state. They were encountering difficulties with quality control and consistency in their assembly line. The traditional examination approaches were labor-intensive and lengthy, commonly causing manufacturing bottlenecks.

Presenting 3D laser scanning to their quality control process was a game-changer. The scanner caught detailed 3D designs of each element, allowing for exact contrast with the original design requirements. Any kind of inconsistencies were instantly recognized, making it possible for speedy corrective actions. This real-time feedback loop significantly improved the uniformity and high quality of the made parts.

Additionally, the digital models worked as a beneficial reference for future production runs, guaranteeing that each set satisfied the rigid sector standards. The efficiency gains were considerable, with lowered inspection times and increased throughput. The manufacturer reported significant expense savings and boosted customer complete satisfaction due to the improved quality and reliability of their items.

Protecting Connecticut’s Historical Heritage

Among one of the most gratifying facets of working with 3D laser scanning has been its application in maintaining Connecticut’s abundant historic heritage. The state is home to many historical sites, each with its unique building and cultural relevance. Protecting these structures calls for meticulous paperwork and reconstruction initiatives.

I had the benefit of dealing with a reconstruction task at a historic mansion in Litchfield. The estate, integrated in the 18th century, had elaborate architectural information that were wearing away with time. Recording these information accurately was crucial for the reconstruction procedure.

Using 3D laser scanning, we created a precise digital reproduction of the mansion. Every cornice, molding, and decorative aspect was caught in spectacular information. This electronic version acted as a referral for the repair team, making sure that the initial craftsmanship was preserved. The capability to picture the entire structure in 3D also permitted us to intend the reconstruction procedure more efficiently, decreasing disruptions to the website.

Additionally, the digital archive created via 3D laser scanning has lasting advantages. It serves as a permanent record of the manor’s original state, which can be important for future remediation initiatives or for instructional objectives. The modern technology has verified to be an important tool in guarding Connecticut’s historical prizes for generations to come.

Overcoming Challenges and Accepting the Future

While the advantages of 3D laser scanning are undeniable, the journey has not lacked its obstacles. Among the main obstacles has been the first investment in the technology. Top notch 3D laser scanners and connected software application can be expensive, presenting a barrier for smaller companies and companies.

Nevertheless, as the modern technology comes to be more extensive, costs are progressively decreasing. Additionally, the effectiveness gains and price savings recognized with using 3D laser scanning commonly warrant the initial financial investment. Numerous firms in Connecticut, including ours, have actually located that the return on investment is substantial, making it a beneficial expenditure.

One more obstacle has actually been the understanding curve associated with running the scanners and interpreting the information. This has actually needed a dedication to training and specialist development. In our firm, we have actually invested in training programs to make certain that our group is proficient in using the innovation and can leverage its complete possibility.

Wanting to the future, I am delighted about the proceeded advancements in 3D laser scanning technology. Technologies such as handheld scanners and drones geared up with laser scanning abilities are making the innovation a lot more obtainable and versatile. These developments will certainly better boost efficiency and open brand-new opportunities across various fields.

Conclusion

Assessing my trip with 3D laser scanning in Connecticut, I am struck by just how transformative this modern technology has been. From building and producing to historical preservation, its impact has actually been profound. The ability to catch and examine accurate 3D information has changed the method we come close to projects, leading to substantial performance gains and price financial savings.

As Connecticut remains to welcome development and technical improvement, I am confident that 3D laser scanning will certainly play a progressively crucial function. It is an effective tool that not just enhances performance however likewise helps us preserve our abundant history and construct a lasting future. For any individual associated with sectors where precision and efficiency are vital, I very recommend checking out the possibility of 3D laser scanning. It has definitely been a game-changer for me and my group, and I think it can be for others as well.

Below are the companies that are authority in the 3D Laser Scanning Technology

| Company Name | Business Description | Website Link |

|---|---|---|

| FARO Technologies | Provides 3D measurement, imaging, and realization solutions, including 3D laser scanning. | FARO |

| Trimble Inc. | Specializes in geospatial, construction, agriculture, and transportation solutions, including 3D laser scanning. | Trimble |

| Leica Geosystems | Offers a wide range of products and services for surveying and 3D laser scanning. | Leica Geosystems |

| Hexagon AB | Provides enterprise software and 3D laser scanning solutions for various industries. | Hexagon |

| Topcon Positioning Systems | Develops precise positioning products and solutions, including 3D laser scanners. | Topcon |

| RIEGL Laser Measurement Systems | Specializes in the research, development, and production of 3D laser scanners and systems. | RIEGL |

| Zoller + Fröhlich (Z+F) | Produces high-quality 3D laser scanners and offers software solutions for data processing. | Z+F |

| Surphaser | Manufactures 3D laser scanning systems known for their accuracy and reliability. | Surphaser |

| Creaform | Provides innovative 3D measurement technologies, including 3D scanners and software. | Creaform |

| Artec 3D | Develops and manufactures professional 3D scanners and software for various applications. | Artec 3D |